ST. ALBANS — A new collaboration is turning locally-made fabric scraps into one-of-a-kind fashion.

Lise-Anne Cooledge, founder of Project Vermont in St. Albans, is sewing tote bags for Warren, a new clothing brand based in Woodstock, Vt.

Launched at the end of October, the bags are made of leftover flannel from Warren’s shirts, keeping the fabric from going to waste. Varied scrap sizes and a patchwork style make each tote unique.

Cooledge had previously done something similar for Outerknown, a California-based retailer, before the company left Vermont. She has since diversified Project Vermont to include ReMarket, a second-hand marketplace on Main Street in St. Albans, other sewing collaborations and community workshops.

“It’s good to give back and also be part of this community more, rather than California,” she said. “That was okay, but this is really fun for me.”

Reviving and reusing

Peter Holoien started Warren in 2024, after falling in love with New England’s history of textile manufacturing. A few years prior, he and his wife had moved from California to New England and were taking weekend trips around the region to explore their new home. They came across several mill towns and old mill buildings that piqued his interest, he said.

“That image of a mill building along a river made me want to do some digging,” Holoien said.

The “Carryall” tote made by Lise-Anne Cooledge of St. Albans for Warren, a new Vermont-based clothing brand. The bag is made from the fabric scraps of the brand’s other clothing items.

Textile manufacturing started to boom in the United States during the War of 1812, when an embargo prevented American merchants from engaging in Atlantic trade. At that time, Great Britain had boasted some of the most advanced textile manufacturing in the world.

This economic problem led some New England merchants, like Francis Cabot Lowell, to open their own textile mills, leading to the famous mill towns of Waltham and Lowell, Massachusetts.

By the Civil War, there were 878 textile factories in New England. Together, they employed more than 100,000 people and produced more than 940 million yards of cloth. But by World War I, most textile manufacturers took their factories south, where labor was cheaper and land was abundant.

“There are a handful of mills around New England that are trying to keep the tradition alive,” Holoien said. “I wanted to see if I could start a brand to help tell their story and help restore the industry a bit here.”

The 100% organic cotton used for Warren’s flannel shirts, for example, is developed by American Woolen in Stafford Springs, Connecticut. The “Six Season Flannel” ($295) is sewn by New England Shirt Co. in Fall River, Mass.

Warren’s t-shirt cotton is made by Draper Knitting in Canton, Mass. and is turned into the “Closeknit Pocket Tee” ($75) by Classic Apparel in Boston.

The apparel is available for sale online and at a handful of Vermont clothing boutiques, like Echo Market in Woodstock and Mysa in Shelburne.

Holoien had admired Cooledge’s work with Outerknown, so when that partnership came to an end, he reached out to her to see if she’d take some of the leftover fabric.

“She has a really positive mission,” he said. “I think all brands should try to achieve what she does in terms of circularity and sustainability.”

On her own time, Cooledge is an avid seamstress, reimagining old clothing into new fashion in the small room at the back of ReMarket. For Warren, she’s produced about 30 “Carryall” totes ($125) and “Holdall” toiletry bags ($50) available for sale online. Other items using fabric cuts are in the works.

“This is me putting my foot forward and saying I am serious about sustainability and doing my part to reduce Warren’s footprint and hopefully inspiring others to do the same,” Holoien said. “Hopefully this is just the beginning.

Teaching the trade

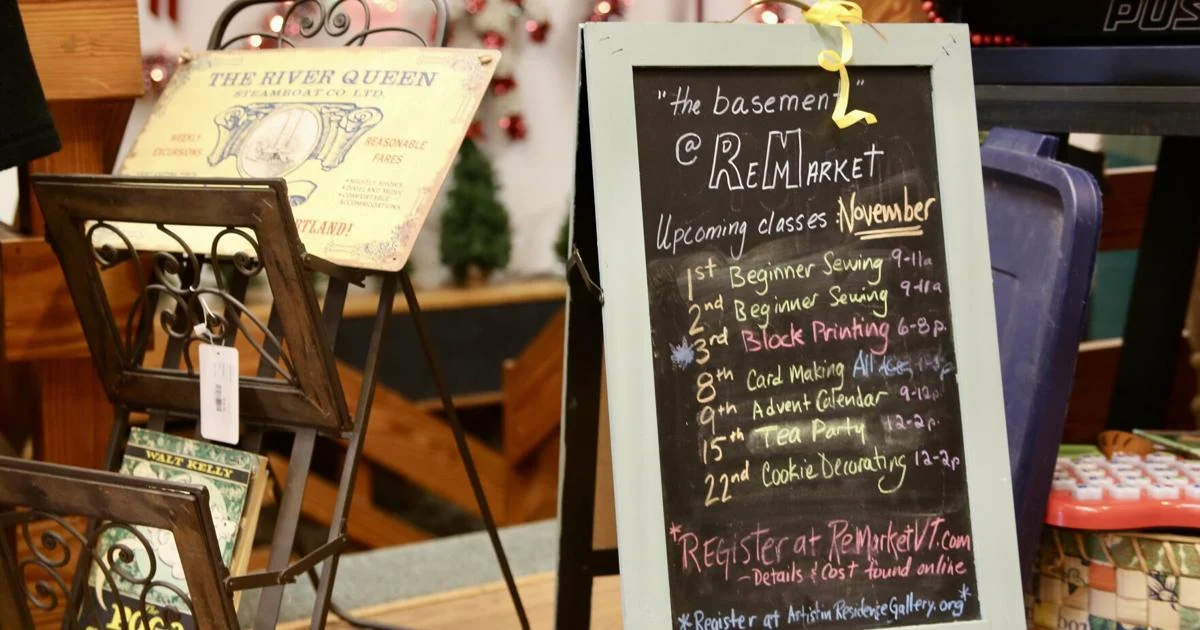

In addition to the sewing collaborations — of which Cooledge said there are more to come — Project Vermont has been hosting a variety of creative workshops for adults and kids in the basement of ReMarket.

From beginner sewing classes to painting, card making and cookie decorating, the monthly sessions fill up fast, showing Cooledge there’s local demand for artistic events. While she teaches the sewing classes, members of the Artist in Residence gallery and other area experts come in to share their unique talents.

“People can rent the space or we can collaborate on a class,” she said. “I’m happy to help or be totally hands-off.”

Find Project Vermont’s class schedule at www.remarketvt.com.