To realize MiMEP’s full potential, we must strengthen its ecosystem and address the remaining technical and logistical challenges.

Highlighted in every single Chief Executive’s Policy Addresses since 2017, the pre-fabricated modular approach as an innovative construction technology has been emphasized for Hong Kong’s development. This approach, using Design for Manufacture and Assembly (DfMA), has transformed construction practices over the last decade, driving efficiencies, fostering innovation, and enhancing safety.

With AECOM having promoted the use of DfMA-inspired prefabricated roof modules with pre-installed MEP for the Hong Kong Port of the Hong Kong-Zhuhai Macao Bridge, we were engaged by the Construction Industry Council (CIC) to develop an industry guideline on extending the DfMA approach into mechanical, electrical and plumbing (MEP) works, now known as multi-trade integrated MEP or MiMEP.

Released in 2021, the industry guideline Reference Material on Adopting DfMA for MEP Works encourages offsite prefabrication solutions, while fully harnessing digital tools such as Building Information Modelling (BIM). In the three years since, there has been a healthy development of MiMEP in Hong Kong. Application has been seen across a variety of government and private sector projects, while MiMEP was also highlighted as a key strategy to expedite housing supply in the Chief Executive’s 2022 Policy Address. However, technical, logistical and supply chain challenges still need to be overcome in order to drive further adoption.

3SS Smart Support solution to manage large MiMEP frames

Compared to traditional methods, MiMEP essentially reorganizes the construction process, replacing low-efficiency on-site construction with high-efficiency off-site construction. The idea is to use DfMA’s assembly line concept, combining parallel off-site and on-site construction with streamlined logistics processes, and ensuring full preparation for future maintenance.

MiMEP can significantly enhance productivity, work efficiency and quality, while improving workers’ safety and reducing site waste. However, since MiMEP aims to integrate multiple systems into a single, cohesive module, a more elaborate and robust concept is needed for transportation protection, on-site hanging and facilitating construction. AECOM has developed the Three SS (3SS) Smart Support solution to provide a framework that addresses these technical challenges and encourages the adoption of MiMEP.

Tackling logistics issues through digital solutions and careful planning

MiMEP logistics are inherently challenging. Issues include costs, time, coordination of off-site/on-site aspects, finding suitable suppliers, transportation costs, and customs clearance. Nowadays, digital solutions have emerged to track logistics and ensure long-distance travel does not cause potential delays.

In Hong Kong’s West Kowloon Terminal Topside Development, AECOM was able to overcome construction difficulties by using multi-trade components in the tunnel connecting the topside development to an off-site seawater cooling system plant room, with logistics arrangements for installation pre-planned using 4D software.

However, more mature solutions are still needed to address certain issues when adopting MiMEP. For instance, the large size and weight of MiMEP modules can present a bottleneck for on-site logistics, requiring specialized equipment and careful planning.

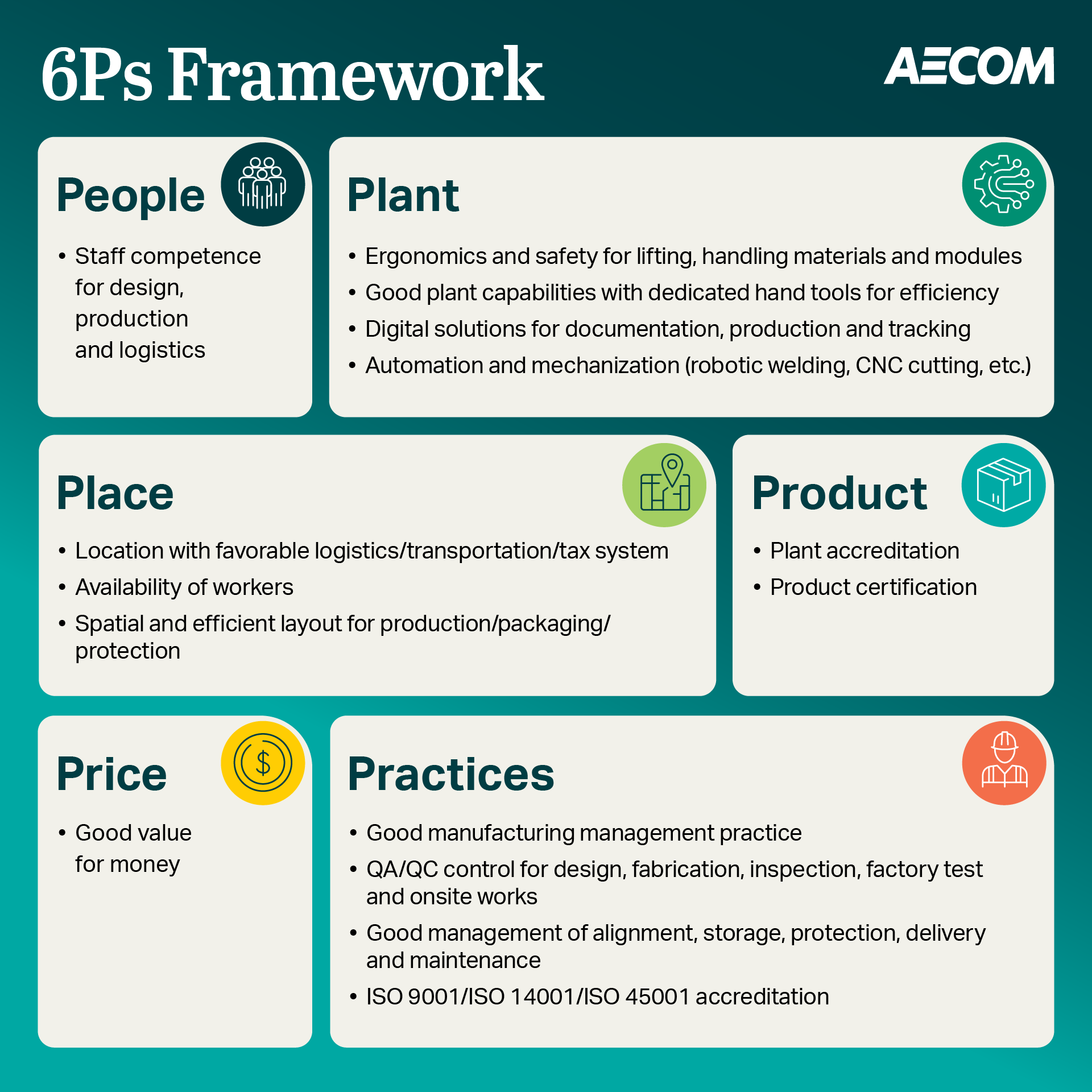

Application of the 6Ps Framework to identify suitable suppliers

A solid base of suppliers is also crucial for further adoption of MiMEP. Supply chains in Hong Kong, the Greater Bay Area and further into Mainland China have emerged to meet this demand. Yet, the market is still developing as we now require a broader range of skillsets beyond just MEP, for instance in digital and logistics. Our 6Ps serve as a checklist to help make an informed decisions when selecting a suitable supplier:

Advancing the MiMEP ecosystem

Three years after publication of AECOM’s industry guideline, both the public and private sectors in Hong Kong have shown a growing interest in adopting MiMEP. As it continues to gain traction in the industry, the concept will evolve and develop. There is no one-size-fits-all approach in this case, and stakeholders will need to identify project-specific drivers such as a client’s values and project KPIs, supply chain capability and degree of repeatability to create a viable MiMEP solution.

Our goal is to continue to facilitate wider adoption of MiMEP in Hong Kong by collaborating with industry partners. To achieve this, four steps are essential:

- Raise awareness through education and promotion

- Engage with stakeholders to create the demand

- Enhance supply chain collaboration/ecosystem

- Build up local capabilities and skills

By focusing on these steps, we can solidify MiMEP’s role in the Hong Kong construction industry, helping to enhance productivity, quality and safety, while achieving environmental sustainability.