By Alexander Miller, consultant in energy markets. Eurasia Business News, December 11, 2024. Article n°1330.

A groundbreaking new iron-making technology developed by Chinese researchers promises to revolutionize the global steel industry. This innovative method, known as flash iron-making, significantly enhances efficiency and reduces environmental impact, achieving a staggering 3,600-fold increase in production speed compared to traditional methods.

Overview of Flash Iron-Making Technology

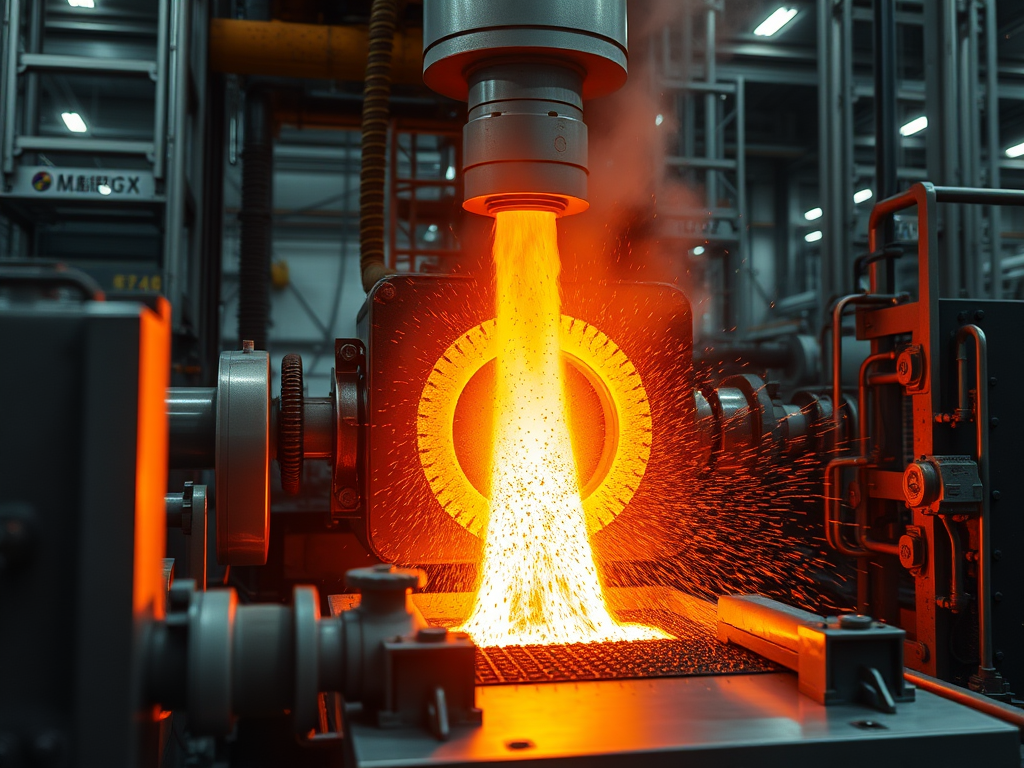

Speed and Efficiency: The flash iron-making process can complete the iron production in just three to six seconds, a drastic reduction from the five to six hours required by conventional blast furnaces. This rapid process is made possible by injecting finely ground iron ore powder into a superheated furnace, which triggers an explosive chemical reaction that produces high-purity liquid iron droplets.

The flash ironmaking technology is an innovative process that uses iron ore concentrate directly without further treatment. The fineness of the concentrate particles allows a very rapid reaction rate, thus requiring residence times measured in seconds instead of the minutes and hours it takes to reduce pellets and even iron ore fines.

Utilization of Low-Grade Ores: One of the significant advantages of this new method is its effectiveness with low or medium-yield ores, which are abundant in China. Traditionally, the steel industry has relied on high-grade ores, often imported at great expense from countries like Australia and Brazil. The new technology allows for the efficient use of these lower-grade resources, potentially reducing costs and reliance on imports.

Environmental Benefits

Reduction in Carbon Emissions:

Iron and steel manufacturing is among the most energy-intensive industries. Ironmaking accounts for the major share of total energy use in steel production in integrated steel mills that use blast furnaces and basic oxygen furnace.

By eliminating the need for coal-based coke—one of the primary sources of greenhouse gas emissions in steel production—this technology could help the steel industry achieve near-zero carbon dioxide emissions. Estimates suggest that energy consumption could be reduced by over one-third, significantly lowering the environmental footprint of steel manufacturing.

Commercial Viability: The flash iron-making technology has already entered commercial production, with a specially designed vortex lance capable of injecting up to 450 tonnes of iron ore particles per hour. A reactor equipped with three such lances has the potential to produce approximately 7.11 million tonnes of iron annually.

This innovative approach not only enhances productivity but also aligns with global sustainability goals by addressing significant environmental challenges associated with traditional steel production methods. As China leads in steel manufacturing capacity, this advancement could reshape the industry landscape, making it more efficient and environmentally friendly.

Our community already has nearly 145,000 readers!

Subscribe to our Telegram channel

Follow us on Telegram, Facebook and Twitter

© Copyright 2024 – Eurasia Business News. Article no. 1330.