UK-based technology developer Immaterial has developed a new type of metal-organic framework (MOF) that is more effective than existing MOF technology and can be used for hydrogen storage.

Spun out of the UK’s University of Cambridge in 2015, Immaterial has created monolithic MOFs, or m-MOFs. These m-MOFs have been shown to be highly effective at capturing carbon dioxide at lower cost than traditional methods.

The m-MOF advantage versus MOF powders lies in is the volumetric capacity: that is, the amount of gas that can be stored per unit volume. Twice as much material, for example captured carbon dioxide, can fit in an m-MOF container compared with pellets.

“With [m-MOFs we] can reach carbon dioxide purity levels above 95% and recovery above 95%,” said David Fairen-Jimenez, professor at the University of Cambridge and founder of Immaterial.

“In terms of cost, where amines capture CO2 at €100 to €120 per tonne, we can go down to around €40,” he said.

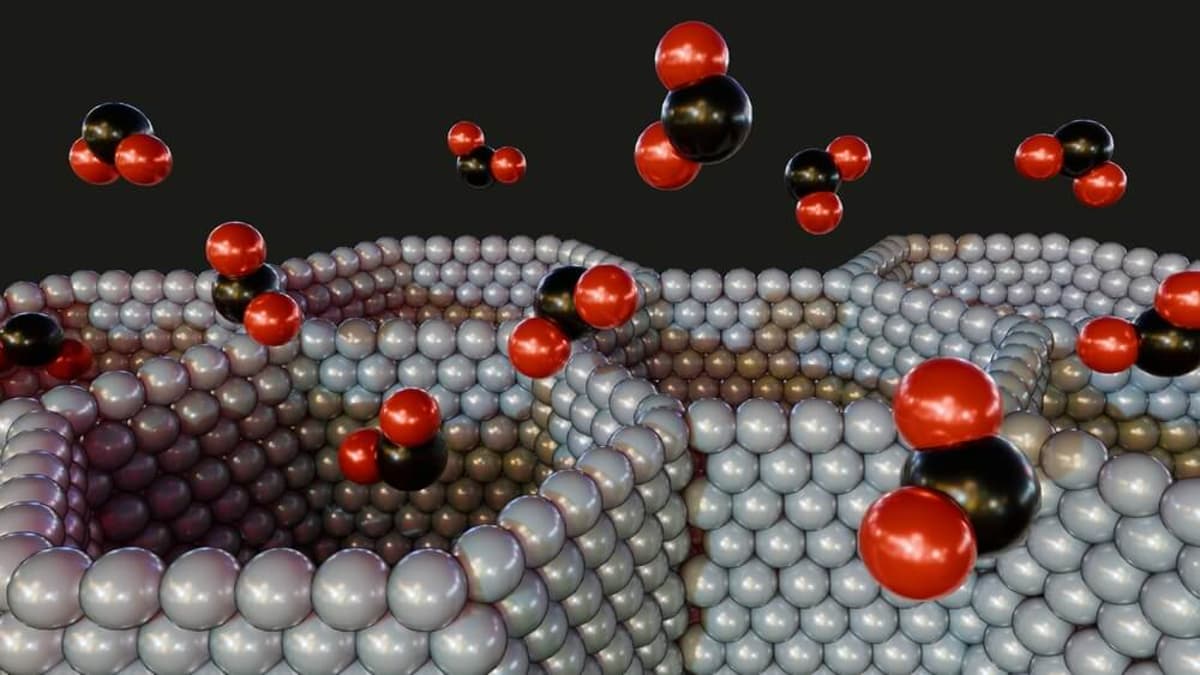

All MOFs are like microscopic sponges or molecular scaffolds filled with tiny, ordered voids. The material is made up of metals that act like joints and organic linkers made of carbon that act like connecting beams.

They have a huge surface area, making them ideal for a wide range of applications including capturing carbon dioxide, separating gases, and storing gases such as hydrogen.

Turning fragile MOF powders into solids without losing porosity has long been a challenge. Whenever mechanical pressure was applied to solid MOF pellets, the porosity – the property that gives MOFs their functionality – collapsed.

This spurred Immaterial to find a better way to ‘densify’ MOFs and make them mechanically stronger.

“We noticed there was a big gap in the way these materials could be deployed in industry,” said Fairen-Jimenez.

The solution came when a researcher came to Fairen-Jimenez with a one-centimetre transparent block instead of a white powder.

“We realised, almost by accident, he had densified the material without collapsing its porosity,” he said. “That discovery solved what had been to that point the biggest barrier to industrial use.”

Left: MOFs are naturally synthesised as powders but are difficult to scale. Right: m-MOFs are more robust and possess high pore volume and density ©Immaterial

Part of this cut in costs that Immaterial sees comes from the technology requiring no pre-treatment – an expensive process necessary when using zeolites or activated carbon.

The company is also exploring how m-MOFs could transform hydrogen storage by replacing conventional high-pressure tanks, which operate at 350 to 700 bar, with systems running at just 25 bar under cryogenic conditions.

This potential was demonstrated in a recent project which saw Immaterial deliver the world’s first cryogenic m-MOF hydrogen tank for a fuel cell bus, funded by the £1bn Net Zero Innovation Portfolio under the Low Carbon Hydrogen Supply 2 Competition.

“It was a very interesting project and also very challenging because it was the first time that we were scaling up this technology,” said Fairen-Jimenez.

The next step is proving that Immaterial’s technology can scale for higher capacity capture and demonstrating the economics.

It has already completed a small-scale demonstrator to validate its materials’ performance and mechanical stability, with a larger pilot expected by the end of this year.

“The only way to prove that this really works is through pilots,” he added. “We need to show that our materials are robust and that our calculations are correct.”

Coming soon in gasworld

Subscribers will soon be able to access the full feature on Immaterial’s m-MOF technology both online and in the November issue of gasworld magazine.