A key aspect of reinvigorating growth in the EV market, after a somewhat slower 2024, will be the deployment of lower cost electric vehicles (EVs). These models will open a new portion of the market.

With the battery accounting for a large portion of the vehicle’s overall cost, developments to improve manufacturing and reduce the cost of the battery are critical.

At the cell level, there are developments in cathode chemistry such as the growing market for LFP (lithium iron phosphate) taken from NMC (nickel manganese cobalt). Then there are new chemistries like LMFP (lithium manganese iron phosphate) and other high manganese chemistries set to enter the market in a big way.

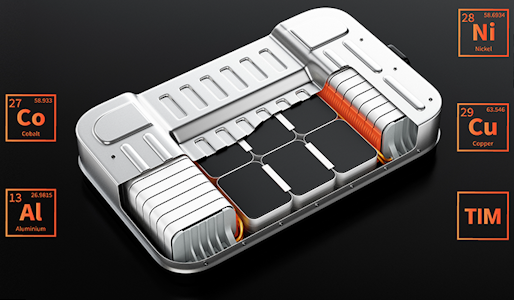

For the pack surrounding the cells, cell-to-pack batteries are becoming a standard option for EV batteries and cell-to-chassis/body are becoming more prevalent. These reduce the quantity and complexity of components for the electrical interconnects, thermal management, electrical insulation, and more.

This webinar provides an overview of the materials required for Li-ion electric vehicle batteries at the cell- and pack-level, and will cover some of the key trends seen in recent years in both aspects of battery design, as well as addressing future trends. The webinar is based on the contents of the upcoming IDTechEx report, “Materials for Electric Vehicle Battery Cells and Packs 2025-2035: Technologies, Markets, Forecasts”.

This webinar covers:

- An overview of materials used in battery cells and battery packs

- Trends in cathode chemistry and anode materials

- Battery pack designs: cell-to-pack and cell-to-body

- The impact on pack materials including thermal management, composite/polymer enclosures, interconnects and insulation